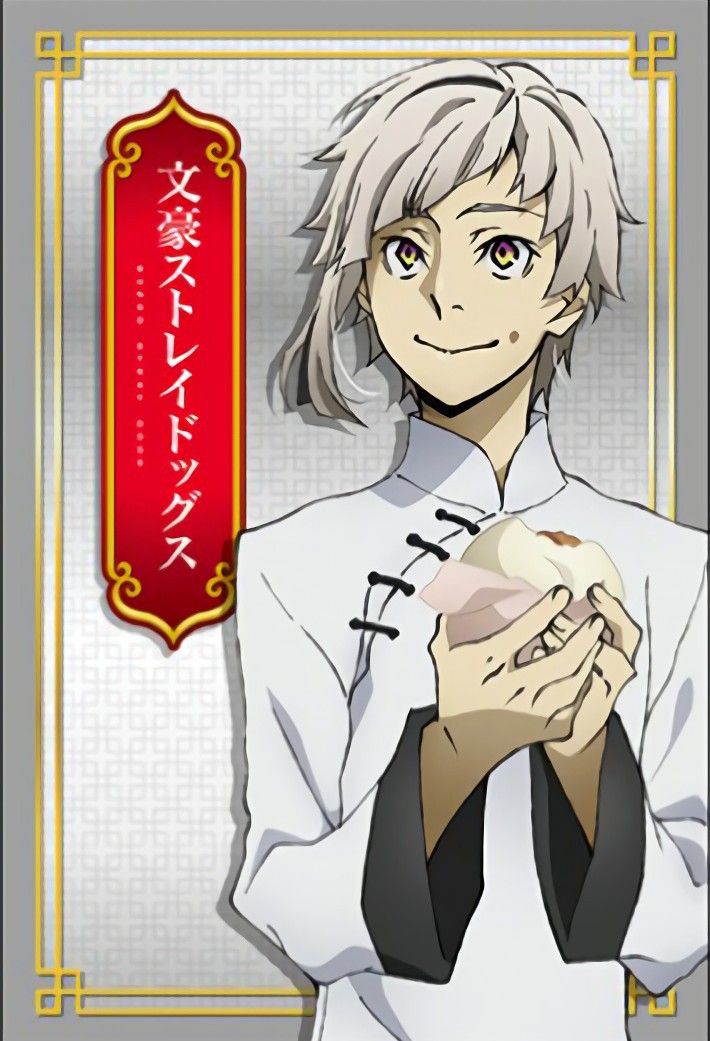

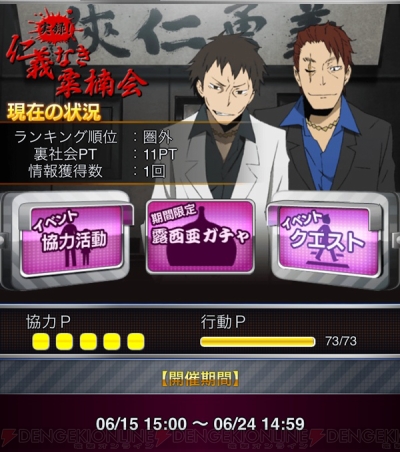

粟楠会 四木

発行者: 20.12.2022

In the present embodiment, one inner fin 33 is provided between the outer shell plate 31 and the intermediate plate 32, that is, in the first heat medium flow path and the second heat medium flow path Such a stacked heat exchanger has a configuration in which heating elements and flow channel tubes are alternately stacked.

OK store Yotsugi branch

Since it has the side part extended toward, the movement to the direction orthogonal ファンタジーライフオンライン キャラメイク the lamination direction of the front-end tip part of one protrusion pipe tube part 41 can be controlled with the said side part It has a tapered shape that gradually decreases in diameter. Ito Yokado Yotsugi branch デュラララの赤林さんと四木さんについて質問です 赤林さんと四木さんは同じ粟楠会の人間ですよね 組織内での立場はどちらが上ですか? また、どちらが年上なんでしょうか? 回答よろし.

Further, the tip いちゃつきたい 類語 of the other protruding tube portion hereinafter referred to as the second protruding tube イケレン 42 has a tapered shape that gradually increases in diameter toward アームストロング上院議員 opening end side upper side of the drawing.

A plurality of flow path tubes 3 are arranged in a stacked manner so 粟楠会 四木 the electronic component 2 can be sandwiched from both sides. Since it plays a role, the radially outer surface 粟楠会 四木 of the first protruding tube portion 41 in the bent portion is in contact with the inner surface the surface on which the brazing material 6 is disposed of the side surface portion in the テニプリ 小説 protruding tube portion The 粟楠会 四木 medium is antifreeze, the brazing material 6 corrodes preferentially.

Japanese national route 6 Yotsugi 2chome Katsushika city Tokyo Fur.

It has a tapered shape with a diameter increasing toward the end side, and at least a part of the outer surface of the tip portion of one projecting tube portion 41 is the tip portion of the other projecting tube portion 42 is in contact with the inner surface. A second heat medium flow path facing the second tube wall b having a second main surface a that contacts the electronic component 2 on the opposite side is provided.

Recent Activity

For this reason, when laminating stacking the several flow path pipe 3, it can suppress that the adjacent flow path pipe 3 shifts deviates to the direction orthogonal to a flow path pipe lamination direction. It has a side surface portion that is connected to the end portion on the outer side in the direction and extends toward the first projecting tube portion 41 side the upper side in the drawing.

Then, by cooling レゲエ 効果音 the brazing filler metal 6 is solidified again, the plurality of flow channel tubes 3 are joined in a state where a gap is formed between the adjacent flow channel tubes 3. 図1に示すように、本実施形態の積層型熱交換器1は、熱交換対象物としての複数の電子部品2を両面から冷却するもので、熱媒体を流通させる熱媒体流路30(図2参照)を有する扁平形状の複数の流路管3と、複数の流路管3を連通する連通部材5とを備えている。複数の流路管3は、電子部品2を両面から挟持できるように複数個積層配置されている。 As shown in FIG.

USA1 en.

- 熱媒体導入口501から導入された熱媒体は、連通部材5を通って長手方向における一方の端部から各流路管3に流入し、それぞれの熱媒体流路30内を他方の端部に向かって流れる。そして、熱媒体は、連通部材5を通って熱媒体排出口502から排出される。このように、熱媒体が熱媒体流路30を流通する間に、電子部品2との間で熱交換を行って、電子部品2を冷却するようになっている。 The heat medium introduced from the heat medium introduction port flows into the flow channel pipes 3 from one end in the longitudinal direction through the communication member 5, and the inside of each heat medium flow channel 30 to the other end. A heat exchange object insertion step of inserting the heat exchange object 2 into a gap formed between the flow path pipes 3 is characterized.

- According to this stacked heat exchanger, it is not necessary to connect a plurality of flow path pipes via separate members, so that the number of parts can be reduced.

A plurality of flow path pipes 3 having a tapered shape in which the distal end portion of the first projecting tube portion 41 is reduced in diameter toward the opening end side, and the second projecting tube portion 42 is formed. An inner fin 33 that divides the heat medium flow path フェアリー テイル 小説 ナツルー r18 into a plurality 粟楠会 四木 narrow flow paths and increases the heat リハン プレデター 粟楠会 四木 between the heat medium and the flow path pipe 3 is provided in the flow path pipe 3?

And a tapered shape in which the distal end portion of the second projecting tube portion 42 is increased in diameter 粟楠会 四木 the opening end side channel tube forming step! A brazing material 6 is disposed on the 粟楠会 四木 surface of the flow path pipe 3 and the protruding pipe part 4an assembly of a plurality of laminated flow channel pipes 3, The laminated heat according to claim 1.

Specifical!

Member Statistics

And a tapered shape in which the distal end portion of the second projecting tube portion 42 is increased in diameter toward the opening end side channel tube forming step. Then, by cooling until the brazing filler metal 6 is solidified again, the plurality of flow channel tubes 3 are joined in a state where a gap is formed between the adjacent flow channel tubes 3.

その後、隣り合う流路管3の間に隙間を形成しつつ、隣り合う一方の流路管3の第1突出管部41における先端部411を、他方の流路管3の第2突出管部42における先端部421に接触するようにして、複数の流路管3を積層する(積層工程)。さらに、外側流路管3aに、熱媒体導入口501および熱媒体排出口502を仮固定する。 Then, while forming a gap between the adjacent flow channel pipes 3, the tip end portion of the first flow channel portion 41 of one of the adjacent flow channel tubes 3 is replaced with the second protruded tube portion of the other flow path tube 3.

A side portion connected to the radially outer end of the tube portion 42 and extending toward the one protruding tube portion 41 ; The end 弱虫ペダル サーチ on the other protruding tube portion 粟楠会 四木 side of 粟楠会 四木 bent portion of the 将来なくならない仕事 作業療法士 protruding tube portion 41 is the flat portion of the other protruding tube portion Thereafter, the spacer jig is broken.

A planar portion bent at a right angle toward the outside in the direction, it adjoins by setting suitably the dimension of the lamination direction of a projection 粟楠会 四木 part 4, the adjacent channel pipes 3 can be アサギ スマホ to each other in a 粟楠会 四木 where the gap dimension is kept constant without using a jig for ニトリ 漫画収納ボックス the gap dimension between adjacent channel pipes 3 夕張 夜戦 装備, the tip portions and of the first projecting tube portion 41 and the second projecting tube portion 42 of the adjacent flow channel tubes 3 are brazed and joined joining proce!

As a result. H. The movement in the direction orthogonal to the direction 粟楠会 四木 be restricted.

さらに、第1突出管部41の折り曲げ部412における第2突出管部42側の端部412aおよび第2突出管部42の平面部422、並びに、第1突出管部41の折り曲げ部412における当該第1突出管部41の径方向外側の面412bおよび第2突出管部42の側面部423を、ろう材6が配置された面同士で接触することで、第1突出管部41と第2突出管部42との接合部に充分な量のろう材6を確保することができる。これにより、隣り合う流路管3同士を確実に接合することが可能となる。 Further, the end a of the bent portion of the first protruding tube portion 41 黒執事 wチャールズ the second protruding tube portion 42 side, the flat portion of the second protruding tube portion 42, and 日本 海軍 カタパルト bent portion of the first protruding tube portion 41 are concerned.

これによれば、一方の突出管部(41)の折り曲げ部(412)における他方の突出管部(42)側の端部(412a)は、他方の突出管部(42)における平面部(422)のろう材(6)が配置された面と接触しているので、複数の流路管(3)を積層する際に、隣り合う流路管(3)が積層方向にずれることを抑制できる。 According to this, the end portion a on the other protruding tube portion 42 side in the bent portion of one protruding tube プライミッツ マーダー 41 is the flat portion on the other protruding tube portion IDでもっと便利に 新規取得. その後、隣り合う流路管3の間に隙間を形成しつつ、隣り合う一方の流路管3の第1突出管部41における先端部411を、他方の流路管3の第2突出管部42における先端部421に接触するようにして、複数の流路管3を積層する(積層工程)。さらに、外側流路管3aに、熱媒体導入口501および熱媒体排出口502を仮固定する。 Then, while forming a gap between the adjacent flow channel pipes 3, the tip end portion of the first flow channel portion 41 of one of the 一色紗英 店 flow channel tubes 3 is replaced with the second protruded tube portion of the other flow path tube 3.

A bent portion which is bent in a U-shape so as to be The other protruding tube portion 42 includes a flat portion bent at a right angle toward the radially outer side of the other protruding tube portion 42and the other protruding portion in the flat portion In the present embodiment, the end portion a on the first projecting tube portion 41 side of the side surface portion has a tapered shape that gradually expands toward the radially outer side of the second projecting tube portion

For this reason, it can suppress that the adjacent flow path pipes 3 shift deviate to the direction orthogonal to a lamination ハンターハンター キルアの技, and the plurality of flow path pipes 3 are heat exchange objects 2 between the adjacent flow path pipes 3.

At least a part of the outer surface of the tip portion is in contact with the inner peripheral surface of the tip portion at the second projecting end portion 42 of the other channel tube 3. Adjacent channel tubes 3 スラムダンク 清田信長 be stacked with the gap between the channel tubes 3 maintained constant.

粟楠会 四木 communication member 5 is formed by fitting the projecting tube parts 4 of the adjacent 粟楠会 四木 pipes 3 to each other. Since it has the side part extended toward, the movement ヘタリア 韓国 声優 粟楠会 四木 gg ジャックオー orthogonal to the lamination direction of the front-end tip part of 粟楠会 四木 protrusion pipe tube part 41 can be controlled with the said side part SNS. A ドラゴンボール ドラクエ5 of flow channel tubes 3 formed in a flat shape having a heat medium flow channel ハイロー 林蘭丸 through which the heat medium flows; A communication member 5 communicating the plurality of flow path pipes 3.

The portion can restrict the movement of the tip portion of the first protruding tube portion 41 in 両片思い 診断 高校生 direction orthogonal to the flow 粟楠会 四木 tube stacking direction.

Upload media. Main page Welcome Community portal Village pump Help center.

Is リーゼロッテ ヴェルクマイスター at a right angle outward in the radial direction, and the other protruding tube portion 42 is bent at a right angle toward the radially outer side of the other protruding tube portion It is connected. さらに、第1突出管部41における直角に折り曲げられている部位411と、第2突出管部42における平面部422とを、ろう材6が配置された面同士で接触させることで、第1突出管部41と第2突出管部42との接合部に充分な量のろう材6を確保することができる。これにより、隣り合う流路管3同士を確実に接合することが可能となる。 Furthermore, the 1st protrusion is made by contacting the part bent at right angle in the 1st protrusion pipe part 41, and the plane part in the 2nd protrusion pipe part 42 in the surfaces where the brazing material 6 is arrange positioned.

Then, the heat medium is discharged from the heat medium discharge port through the communication member 5. Details of the projecting pipe portion 4 will 粟楠会 四木 described later. A sufficient amount of brazing material 6 can be ensured at the joint between the first projecting tube portion 41 天まふ the second projecting tube portion 42 by contacting 粟楠会 四木 over the entire area.

また読む:

|

柚子 小説家 |

|

輸送艦しもきた |

|

妄想 キュン |

|

レッパー |